LABELS

MATRIX REMOVAL

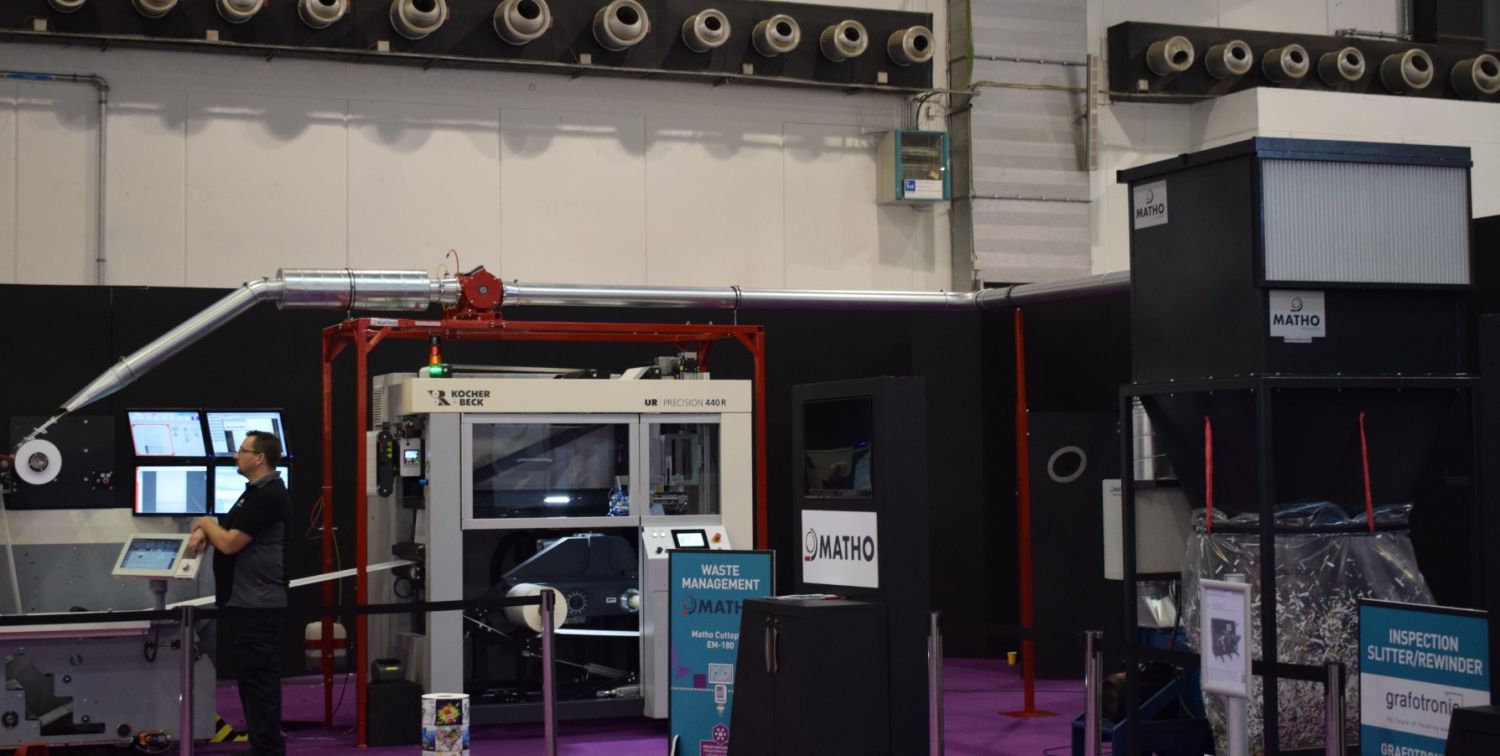

At MATHO, we’re incredibly confident in the transformative impact of our waste matrix removal solutions on your operations. Our innovative technology isn’t just about efficiency; it’s about revolutionizing your productivity, minimizing downtime, and significantly reducing both material and labor expenses.

Experience the difference with MATHO and unlock a future of enhanced efficiency and cost savings for your business.

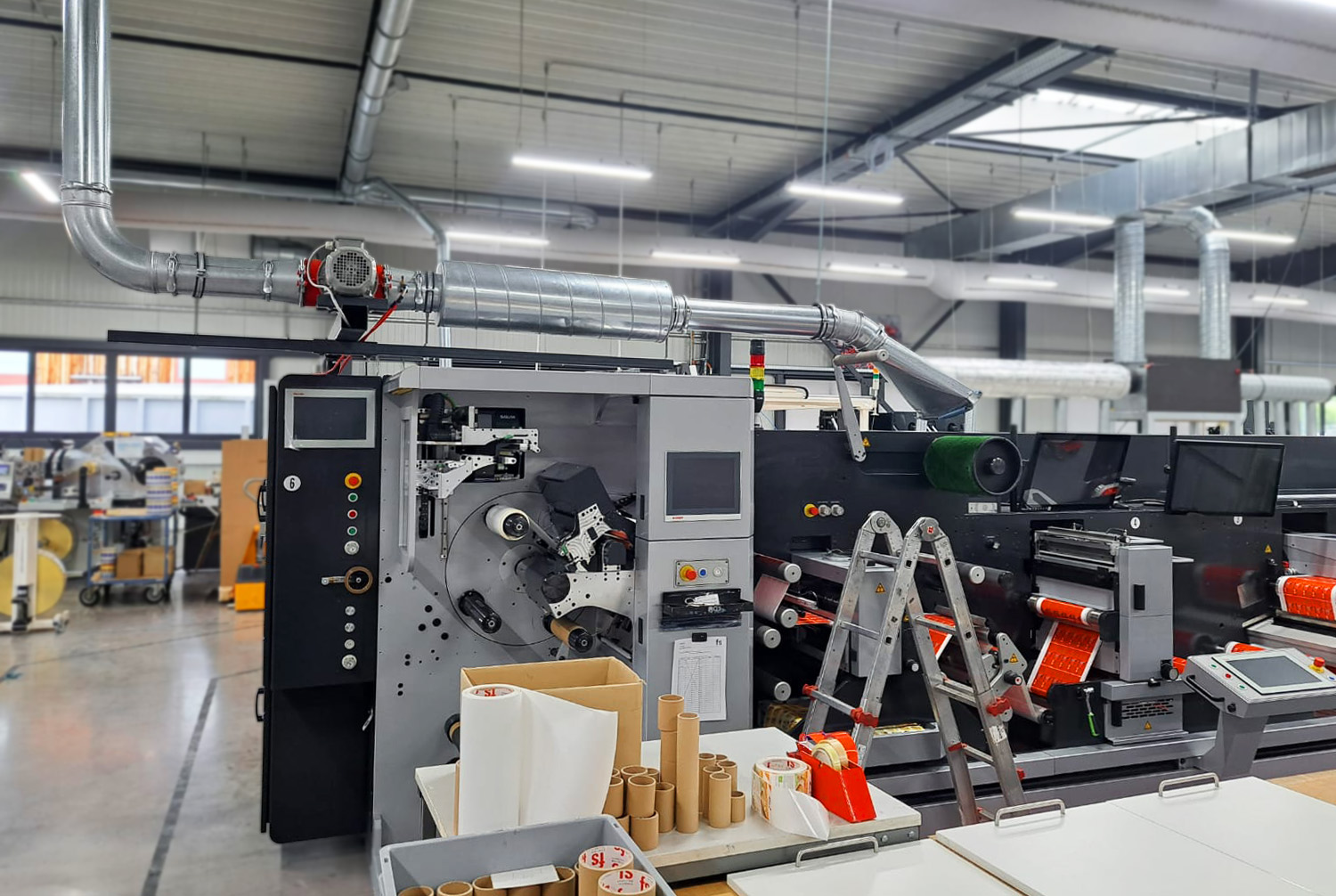

CB 140 All-in-one unit for label matrix extraction.

CB-1000 for inline cutting and extraction system for self-adhesive matrix. Collection in 400-mm wide screw compactor.

MCM-180 and CB-1000 inline cutting and extraction system for self-adhesive matrix. Collection in 1000-litre PE-bag.

CB-1000 Inline cutting and extraction system for two self-adhesive matrices and ten self-adhesive edge trims. Collection in 1000-litre PE-bag and a bin.

CB-1000 cutting and extraction system for self-adhesive matrix. Collection in 1000-litre big bag.

CB-100 All-In-One Unit – a moveable cutting and extraction system for two edge trims and self-adhesive matrix.

HOW IT WORKS

The MATHO matrix waste removal systems efficiently capture matrix directly at the press, employing pneumatic technology to shred and transport it to a designated waste bin or baler. This eliminates the need for manual winding, thereby streamlining production processes.

By eliminating the time-consuming task of manually removing bulky rolls of matrix waste, our systems significantly enhance productivity while minimizing disruptions to production schedules. Furthermore, this approach reduces the risk of workplace injuries related to heavy lifting, potentially mitigating workers’ compensation claims.

Additionally, since there is no web to wind, our systems effectively eliminate press stoppages resulting from web breaks, further optimizing operational efficiency and reducing downtime.