CUTTOPRESS

cENTRAL waste extraction systems

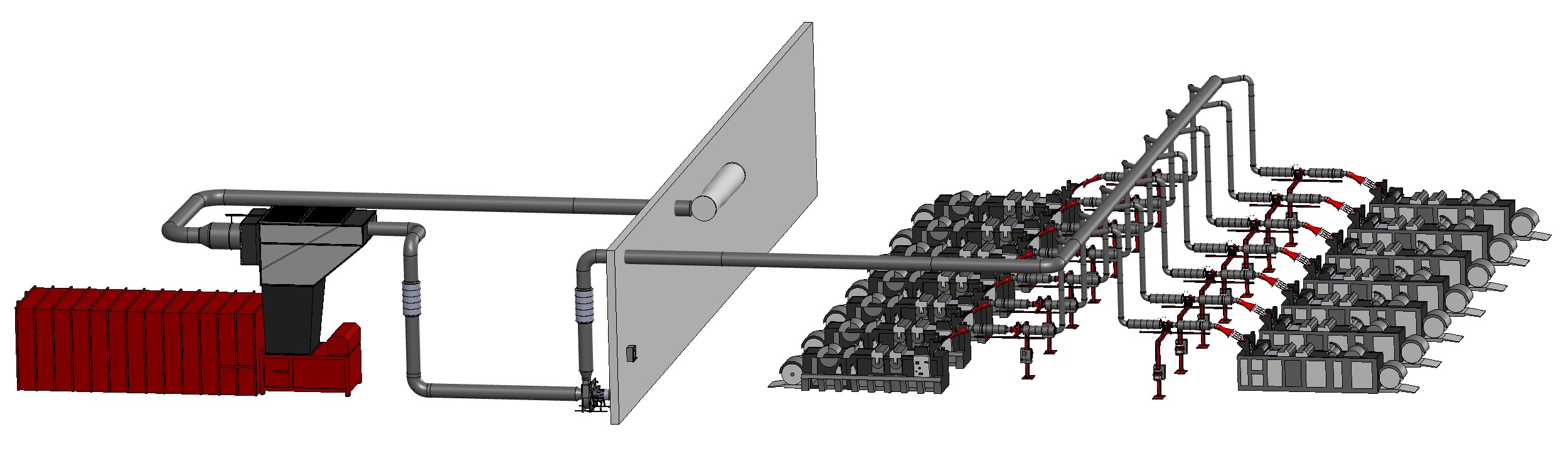

The CP-6000 is a robust central inline cutting and waste extraction system, designed to handle the production waste from mid-sized to large machine groups.

The CP-6000 series is built to efficiently extract production waste from multiple spots across the factory floor. It is designed to work seamlessly with static compactors or press containers to collect, cut, and transport waste materials. This system ensures that waste is managed with minimal downtime, keeping your operations running smoothly and cleanly.

The CP-6000 central waste extraction system is widely applicable across industries that handle high volumes of packaging, plastics, paper, and other production materials that generate waste. It is ideal for use in large-scale production facilities requiring centralized waste collection and disposal solutions.

Additionally, the CP-6000 system is designed with the flexibility for future upgrades or modifications, allowing it to adapt to growing production demands.

Materials that can be processed include:

- Self-adhesive labels

- Cardboard

- Packaging materials (e.g., foils)

- Wood veneer

- Plastics

- Paper

- Textiles

Advantages

- Handles the waste disposal needs of entire production plants.

- Supports higher machine speeds by keeping the production environment clear of waste.

- Ensures constant web tension during the exhaust process.

- Adjustable suction power via automatic control (with frequency changer and electro-pneumatic slide gate valves).

- Guarantees a clean production environment with minimal downtime for waste removal.

- Allows for non-stop production when integrated with unwinder and rewinder systems.

SYSTEM EXAMPLE

& OPTIONS

Options

- Anti-Static System: Reduces static buildup for safer and more efficient operation.

- Material Separation System: Enhances the separation of different types of waste materials.

- Professional Dust Filter System: Helps in maintaining air quality by removing fine dust particles.

- Sound Control Housing: Minimizes noise from the transportation fan for a quieter working environment.

- Summer-Winter Valve for Air Return: Adjusts air return settings based on seasonal requirements for energy efficiency.

- Air Return System: Further improves the system’s energy efficiency by returning filtered air to the production environment.

- Static Compactor / Portable Compactor / Container: These options can be added for flexible waste collection solutions (note: these are not part of the MATHO system but are compatible with it).

CONTACT

US

Welcome to our contact page! How can we assist you today? Whether you’re seeking guidance from one of our applications specialists or interested in obtaining a quote, we’re here to help. Please feel free to reach out to us using the form below, and we’ll get back to you promptly.

"*" indicates required fields