GR CUTTER

Inline Cutting Units

A unique inline cutter that processes waste, integrating into waste systems with high throughput and reliability.

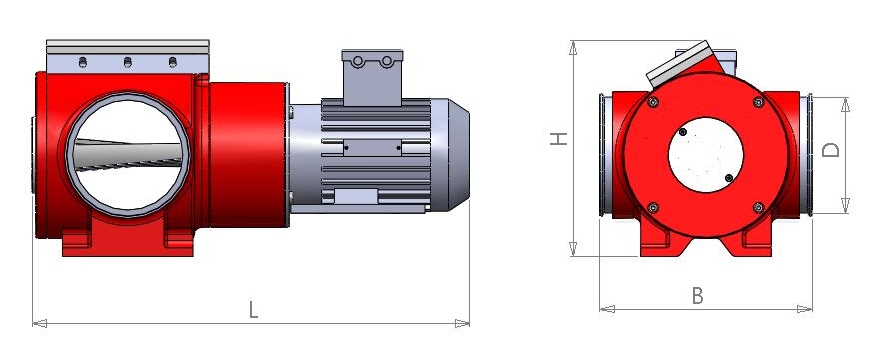

The Matho GR Cutter is an innovative inline cutting unit designed to efficiently process continuous and endless residual materials into smaller fragments. Our cutting-edge units seamlessly integrate into both new and pre-existing waste extraction systems, ensuring optimal performance and waste management solutions for various industries.

GR Cutters are unique inline cutters designed to seamlessly integrate into existing waste extraction systems. They offer solutions for numerous applications, efficiently cutting a wide variety of materials with minimal air resistance, high throughput rates, and exceptional reliability.

The GR 100, 160, 180, and 200 cutters are specifically engineered for cutting production waste. The cutter is equipped with 2 or 3 rotating knives, and a fixed blade. These versatile units can handle various residual materials from production processes, such as edge strips and stamped grids, within pipe systems.

Materials that can be cut include:

• Self-adhesive labels

• Various types of cardboard

• Packaging materials

• Wood veneers

• Synthetic materials (plastics)

• Paper

• Textiles

• Foils

• Additional materials upon request

Benefits

- High Reduction of Waste Volume: Effectively decreases the volume of production waste.

- Versatile Cutting Capability: Capable of cutting a wide range of materials.

- Compact Design: Optimized for space-saving installation.

- Genuine Scissor-Knife Cut: Ensures precise and clean cuts.

- Low Noise: Scissor cut principle assures low noise during operation.

- High Throughput: Maintains high processing speeds.

- Low Energy Consumption: Energy-efficient operation.

- Low Air Resistance: Minimizes impact on airflow within extraction systems.

- Low Operation Costs: Cost-effective maintenance and operation.

- Flexible placement: Cutter can be mounted in any direction.

| GR-100 | GR-160 | GR-180 | GR-200 | |

|---|---|---|---|---|

| D (mm) | 100 | 160 | 160 | 200 |

| U/min. | 3000 | 1500 | 1500 | 1500 |

| L (mm) | 392 | 517 | 655 | 720 |

| B (mm) | 254 | 284 | 293 | 350 |

| H (mm) | 198 | 208 | 300 | 310 |

| Power (KW) 50Hz / 60Hz | 0,55 / 0,66* | 0,75 / 0,9* | 0,75 / 0,9* | 1,5 / 1.8* |

| Weight (kg) | 22** | 34** | 65** | 80** |

| Knives | 2 or 3 | 2 or 3 | 2 or 3 | 2 or 3 |

| RPM 50Hz / 60Hz | 1500-3000 / 1800-3300 | 1500-3000 / 1800-3300 | 1500-3000 / 1800-3300 | 1500 / 1800 |

* Power data are default values. Those are changeable, if requested

** Weight includes the motor.

APPLICATION

IMAGES

CONTACT

US

Welcome to our contact page! How can we assist you today? Whether you’re seeking guidance from one of our applications specialists or interested in obtaining a quote, we’re here to help. Please feel free to reach out to us using the form below, and we’ll get back to you promptly.

"*" indicates required fields