CuttoBag Series

cutting and extraction systems

An all-in-one solution for efficient waste extraction, reducing volume and costs, with easy integration and maintenance.

The CB product family offers a comprehensive range of cutting and waste extraction systems designed to enhance the efficiency and flexibility of manufacturing processes. These systems cater to a variety of production needs, from handling endless trim and self-adhesive matrices to managing waste from one or multiple machines across a production line.

Matho’s CB units provide a cost-effective and efficient solution for waste management, featuring high availability, reduced waste volume, and low operational costs. Both systems are designed for low energy consumption, minimal maintenance, quiet operation, and easy integration into new or existing systems.

CB 120/140

All-In-One Mobile Cutting and Waste Extraction System

The CB-120/140 models are compact, mobile units ideal for handling non-adhesive and self-adhesive edge trims, die-cut pieces, and matrix waste. Their robust design allows for easy movement between machines, making them a versatile solution for dynamic production environments. Tailored for production lines engaged in label converting, film extrusion, coating & lamination, slitting & rewinding, printing, or packaging production, this unit ensures seamless and efficient operations.

Additionally, these units can be customized with integrated material separation systems, enabling efficient recycling processes.

Key Features

- Handles various types of waste, including static and sticky materials

- Simple controls with push buttons and speed dial

- Silent operation with big silencers

- F7 filter with an option to add a HEPA filter

- 900-litre bag for extended operation time

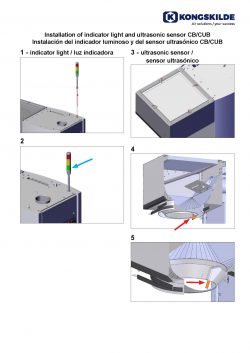

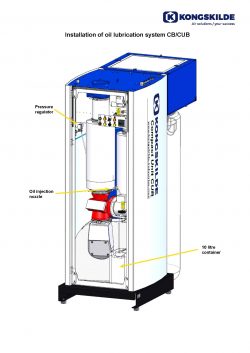

- Upgrades available to include an oil mist system, antistatic kit, HEPA filtration, level sensor with light tower kit for monitoring, endless bag kit for extended operation, and a waste compactor for continuous operation.

Benefits

- Cost-effective cutting and extraction system

- Reduced waste volume with an integrated cutting module

- Compact design with a minimal footprint

- Mobile and moveable system

CB 1000

Robust Stationary Waste Extraction System

The CB-1000 models are advanced waste extraction systems designed to capture and cut waste from either a single production line or multiple machines. These systems are highly customizable, offering tailored solutions to meet specific customer needs. Shredded waste can be efficiently transported through a piping system to various destinations, such as a PE bag or screw compactor, which can be positioned either inside or outside the facility.

The CB-1000 systems are also expandable, allowing for the integration of additional machines over time. Optional features such as dust filters, air recirculation systems, and fan sound enclosures further enhance their functionality and adaptability.

Key Features

- Handles various types of waste, including static and sticky materials

- Collection options include: PE-Bag, octabine, roll container/bin, screw compactor, and more.

- Fully customized to your production

- Expandable design allows for the integration of additional machines over time

- Options include: dust filter, air return system with air release inside the building, sound enclosure for the transportation fan, antistatic system, electro-pneumatic valve system (PLC-controlled), material separation system

Benefits

- Handles higher production speeds

- Reduced waste volume with an integrated cutting module

- High throughput

- Reduction of labor costs by eliminating manual waste handling

TECHNICAL

DATA

CB-120/140

| Power supply | 3 x 380-480 V 50/60 Hz CE UL/CSA |

| Current | 16 A |

| Material thickness | 20 - 300 µm |

| Blower output CB-120 / CB-140 | 2.2 kW /4 kW |

| Cutter motor | 0.75kW |

| Weight | 400 |

| Height x Width x Length | 2,150 x 800 x 1,570 mm |

| Pipe connection at inlet | OK 160 |

| Bag capacity | Ø1,1500 x 2,240 mm (approx. 900 liter) |

| Max noise level | 80 dBa |

| Compressed air supply for oil system (accessory) | Min. 4 bar - max. 6 bar Consumption: 200L/hour |

DOWNLOADS

APPLICATION

IMAGES

CONTACT

US

Welcome to our contact page! How can we assist you today? Whether you’re seeking guidance from one of our applications specialists or interested in obtaining a quote, we’re here to help. Please feel free to reach out to us using the form below, and we’ll get back to you promptly.

"*" indicates required fields